Assuming responsibility in a holistic manner

Our extensive experience and the high level of knowledge of our team means that we select the most efficient manufacturing process for each product. Thanks to our configuration based on a flexible structure, at JAMAI we are constantly adapting to the customer's needs. In addition, this has an extraordinary impact on our intercompany management capacity.

We adapt and use different processes and materials depending on the type of part and the specific needs of our customers:

STANDARDISED CARBON STEEL

QUENCHED AND TEMPERED CARBON STEEL

QUENCHED AND TEMPERED ALLOY STEEL

STAINLESS STEEL

GREY IRON

NODULAR IRON

ROLLED AND FORGED STEEL

NON-FERROUS (ALUMINIUM AND BRASS)

PRODUCTIVE PROCESSES

PRODUCTIVE PROCESSES

WIDE RANGE OF PRODUCTION PROCESSES

lexible structure according to the needs and type of part.

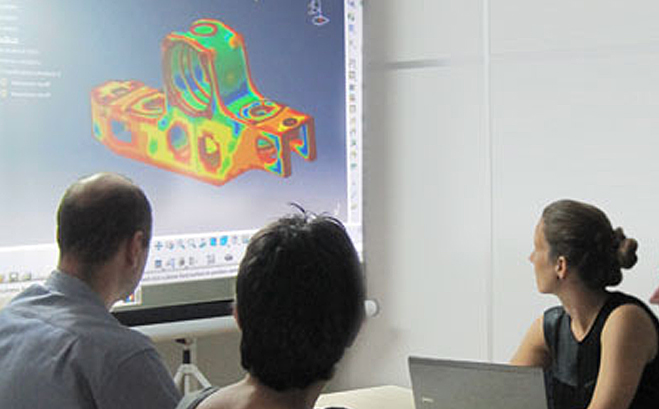

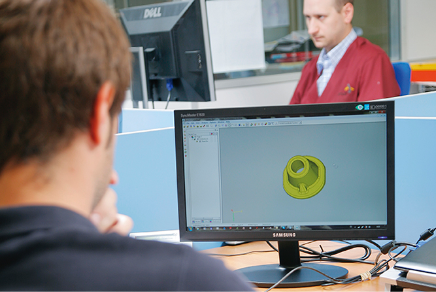

The most advanced technology is materialised in intelligent software that allows us to carry out and ensure a more reliable and efficient analysis for each new design. Through this software, at JAMAI, we design and conduct mould filling and solidification simulations of systems in 3D, as well as design machining tools. Throughout the entire product design phase, the customer actively participates with the JAMAI team, thus reducing risks, deadlines and costs. Even so, we, the organisation, assume all responsibility in terms of project leadership for the design and the development of the part engineering for a correct industrialisation.

Throughout the design process, at JAMAI we make use of automation and parameterisation techniques. The large number of moulds and tooling developed in recent years has allowed us to maintain a large volume of mould subcontractors in various areas that streamline the possibilities offered by more local markets.

DESIGN AND SIMULATIONS

Automation and parameterization with proprietary software.

In JAMAI we manufacture parts in casting, forging, injection, chip removal and we carry out paint finishes, metallising and various surface protections. All this production chain is subjected to a rigorous integral control, incorporating fast and efficient industrialisation processes, as a result of our exceptional "expertise" in product development.

We have 3 production areas located in Spain, China and India.

In our commitment to offer the best service with the best technology, JAMAI has intelligent software and a proprietary system for tracking orders through data capture.

Throughout our years of experience, we have developed a kind of A.I. (artificial intelligence) that brings together launch data, model status, moulds, batch planning, machine loads, inspection times and, together with the information from the shipping lines and their transit time logics, this allows us to provide highly accurate information on the situations and delivery forecasts at our customers' assembly plants.

In addition, customers will soon be able to automatically check the status of their orders to have updated, first-hand information.

MANUFACTURING

We have intelligent software and our own system.

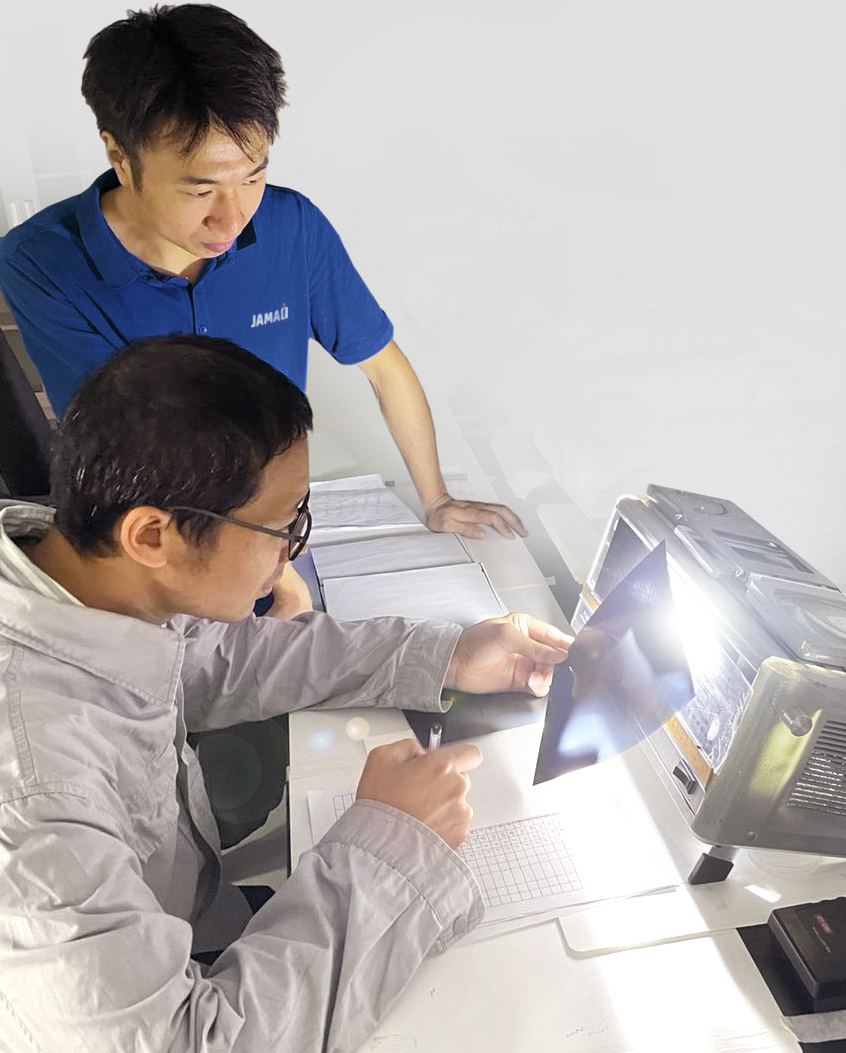

At JAMAI, we meticulously control each and every one of the stages of production of the products in real time. We perform both destructive and non-destructive controls at each stage of the process, documenting every detail.

Computer tools and software allow us to record each step in an optimal way.

MATERIAL CONTROLS

We carry out laboratory tests at each production plant.

NON-DESTRUCTIVE TESTS

JAMAI has its own personnel certified as Level 2 and Level 3 under international standards EN 473 and ISO 9712.

Non-destructive testing available.

DIMENSIONAL CONTROLS

Our inspectors follow the customer's control guidelines and our own internal ones, to check the dimensional validation of all parts during the process and in the final inspection.

Controls in coordinate measuring machines.

INTERNAL CONTROL OF THE FINAL PRODUCT

We perform both destructive and non-destructive controls at each stage of the process, documenting every detail. Computer tools and software allow us to optimally record each step.

INSPECTION

Real time control of each and every production phase.

The flexibility of JAMAI's structure and the design of our own logistics management system allows us to optimally deliver products to the customer's facilities. We have computer tools and intelligent software to manage and streamline the after-sales service, and even efficiently solve possible incidents after product delivery.

Own model IDI (Intelligent Digital Industrialisation)

JAMAI has different software programs for the design and simulation of the foundry, design of machining tools and order tracking. The intelligent management and monitoring of the processes allow to guarantee a better control during all the phases of a project. All these systems contribute to establish JAMAI's own model with the digital component as a common denominator.

LOGISTICS AND AFTER-SALES

We have our own system for logistics management.